Chocolate Twist Packing Machine plays a central role in helping confectionery manufacturers optimize packaging efficiency, improve product handling, and maintain consistent workflow across modern production lines.

In competitive candy markets, packaging is no longer only about wrapping products. It directly influences brand presentation, logistics performance, and consumer experience. Manufacturers today focus on achieving reliable packaging speed, consistent product appearance, and minimal material waste while maintaining smooth integration with upstream and downstream processes.

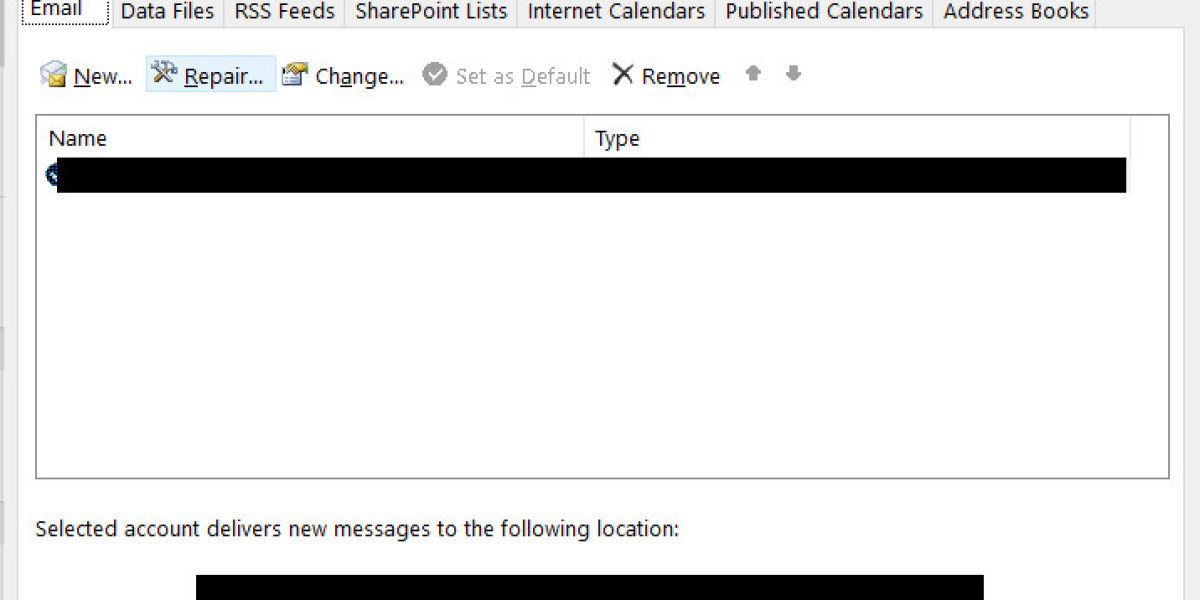

One major improvement brought by modern twist packing systems is workflow stability. Manual packaging often introduces variability due to operator fatigue, inconsistent wrapping tension, and changing handling speeds. Automated twist systems maintain consistent wrapping pressure, precise film alignment, and steady cycle timing, allowing production lines to operate with fewer interruptions and more predictable output levels.

Material efficiency is another key benefit. Packaging film and wrapper consumption represent a significant cost for candy producers. Advanced packaging systems regulate film usage accurately, ensuring each piece receives the necessary protection without excessive material consumption. This approach helps reduce waste generation and simplifies inventory planning for packaging supplies.

Production flexibility also improves significantly. Manufacturers often need to adjust production for seasonal demand, new product launches, or customized packaging campaigns. Modern twist packing equipment can accommodate various candy sizes, shapes, and wrapper designs with minimal changeover time. This adaptability allows factories to respond quickly to shifting market needs without rebuilding entire packaging lines.

Labor optimization becomes easier as well. Automated packaging systems reduce reliance on manual handling, allowing workers to focus on quality inspection, process supervision, and equipment maintenance. This shift supports safer working environments and helps companies allocate human resources more effectively across production departments.

Consistency of product presentation remains essential for consumer trust. Uniform wrapping, symmetrical twisting, and clean sealing all contribute to shelf appeal and perceived product quality. Automated systems deliver stable visual results, ensuring every package meets defined standards regardless of production volume or shift duration.

Maintenance planning also benefits from equipment designed for continuous operation. Modern machines incorporate accessible component layouts, simplified cleaning procedures, and structured inspection schedules. These features support preventive maintenance programs and reduce unplanned downtime, contributing to stable long term production performance.

Supply chain coordination improves as packaging becomes more predictable. With consistent output rates and fewer packaging disruptions, logistics teams can plan storage, shipping, and distribution more accurately. This reliability reduces bottlenecks and supports smoother collaboration between manufacturing facilities and distribution partners.

Sustainability considerations are increasingly important for candy producers. Efficient packaging systems help reduce material waste, improve energy management, and support responsible production goals without sacrificing operational efficiency. These improvements align production performance with broader environmental strategies many companies now prioritize.

Flyloong designs its candy packaging equipment with these operational needs in mind, offering solutions that support long term reliability, adaptable production planning, and practical maintenance management across a wide range of manufacturing environments. This approach allows confectionery producers to upgrade packaging performance while maintaining stable operating costs and predictable production results.

As candy markets continue to evolve, manufacturers who invest in well integrated packaging systems position themselves for consistent growth, improved supply chain coordination, and stronger brand presence in increasingly competitive retail environments.

To explore technical background and application details, you may refer to https://www.flyloong-candymachine.com/news/industry-news/what-is-a-chocolate-twist-packing-machine-everything-you-need.html